Efficiency in the Jobbing Foundry Industry

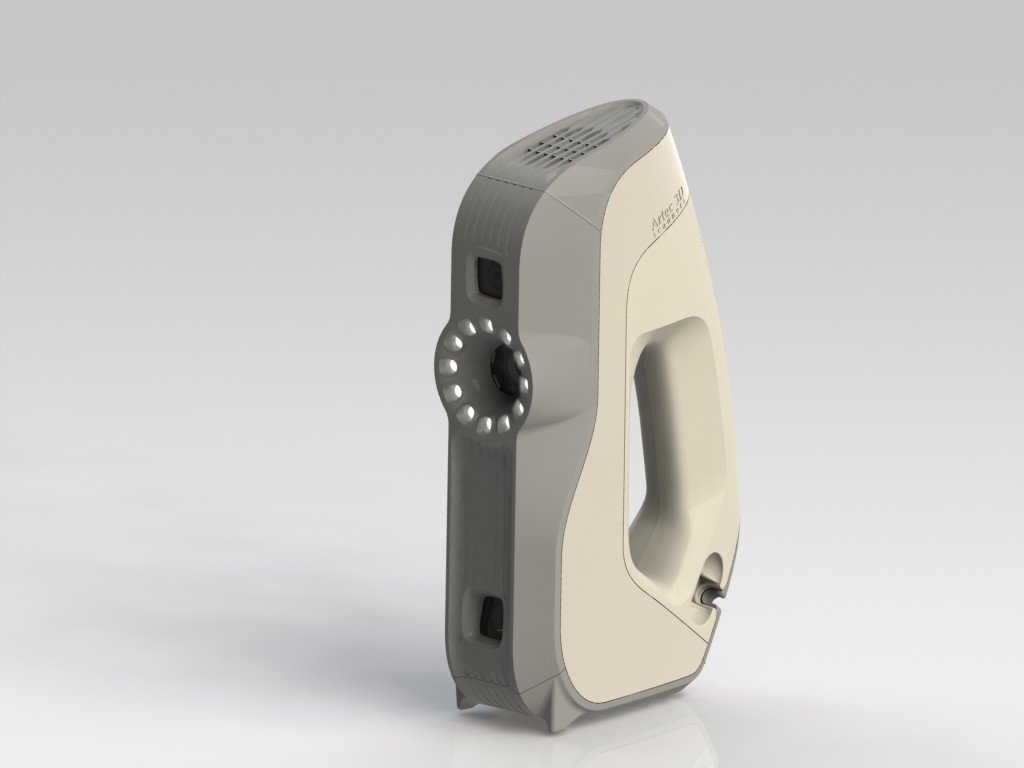

You can slash up to 75% off production time as well as cut losses in the jobbing foundry industry with the market leader in handheld 3D scanners - the Artec Eva.

The Artec Eva is the most popular 3D scanner for a reason. It comes down to accuracy of data capturing, speed of data processing, and portability. This article will examine how casting projects can go from a 7-10 day production span to just 10 hours. How does the Artec Eva slash 75% off production time?

Accurate Data Capturing and Processing

Artec Eva’s speed of processing is the core feature that reduces production time in the jobbing foundry industry. The large field of view allows for a fast capture rate because it can take in a large amount of data at once. The efficiency of data capturing doesn’t end there, the improved technology has a high speed for both data capturing as well as processing.

The accuracy of the Artec Eva data processing allows it to be rendered useful beyond the initial stages of capturing dimensions. Because of its speed, it can be used throughout a project to ensure dimensional control in all stages of the jobbing foundry process. Another feature that improves its efficiency is its portability.

The Power of Portability

The Artec Eva 3D scanner cuts production time because of its ease of maneuverability. Its portability allows it to be versatile in the workplace. Large castings can often prove problematic with their immobile nature. Large castings can now be easily scanned and processed because the 3D scanner can be brought to the project. The Artec Eva’s compact and lightweight composition allows for accurate scanning of hard-to-reach objects as well. Its versatility in maneuverability matches its versatility in scanning capabilities. Using light-scanning technology and a texture sensitive camera, the Artec Eva is able to scan a vast variety of object types which proves very useful when it comes to the dynamacy of the jobbing foundry industry.

Cutting Losses

A common issue in the jobbing foundry industry is the risk of castings cooling unevenly. This can lead to production errors. The joint efficacy improves with the Artec Eva’s portability and fast data capturing because it can identify structural weaknesses in very little time, allowing for mitigating strategies to be implemented sooner rather than later.

The answer to how the Artec Eva can cut such a significant percentage off production time comes down to one thing: efficiency. It improves efficiency when it comes to scanning, processing, and accuracy because it mitigates errors preventing you from going back to the drawing board.

If efficiency is what you strive for in your business, then don’t hesitate to reach out to My Engineering to get your hands on an Artec 3D scanner. If you want to learn more about Artec3d and how to slash production time in the jobbing foundry industry, visit their website!

*Original article and content provided by Artec 3D.